The manufacturing industry faces significant consumer demand and regulatory pressure to embrace sustainable business practices, prompting broader interest and engagement in circular material flows, energy-efficient technologies, socially and environmentally responsible supply chains.

As sustainability consultants, we support leadership teams in their efforts to better understand, and manage, the environmental and social impacts of their product lines while staying competitive in the marketplace.

This guide outlines the common challenges, best practices, and financial benefits of sustainable advancements in manufacturing. See how double materiality and circularity are key to meeting your company’s ESG targets.

Common Challenges for Sustainable Manufacturing

While developing an ESG strategy for sustainable manufacturing, it is important to recognize and prepare for potential challenges related to:

- Regulatory Compliance

Navigating the evolving landscape of state and federal regulations, and corresponding reporting requirements, can complicate project management efforts, especially if your company operates in multiple states and/or countries.

In 2024 alone, the European Union passed a flurry of environmental regulations that impact thousands of U.S. based businesses both directly and indirectly through supply chain relationships. The EU Deforestation Regulation (EUDR) and the Corporate Sustainability Due Diligence Directive (CSDDD, or CS3D) require changes to business practices in order to prove that goods are made legally, and with respect for social and environmental protections. U.S. companies that receive compliance requests from business partners may be caught off-guard by extensive traceability and monitoring requirements which extend to raw materials. - Supply Chain

The procurement of consistent sustainable materials demands time and diligence. To support a global supply chain, maintain a comprehensive list of production materials and engage with suppliers to analyze compliance certifications, pricing, and availability for each component. - Resource Allocation

A transition towards sustainable manufacturing requires dedicated concentration from a range of stakeholders within the company. Apart from workforce time, startup costs might also include investments in new technology, equipment or materials. - Marketing & Communication

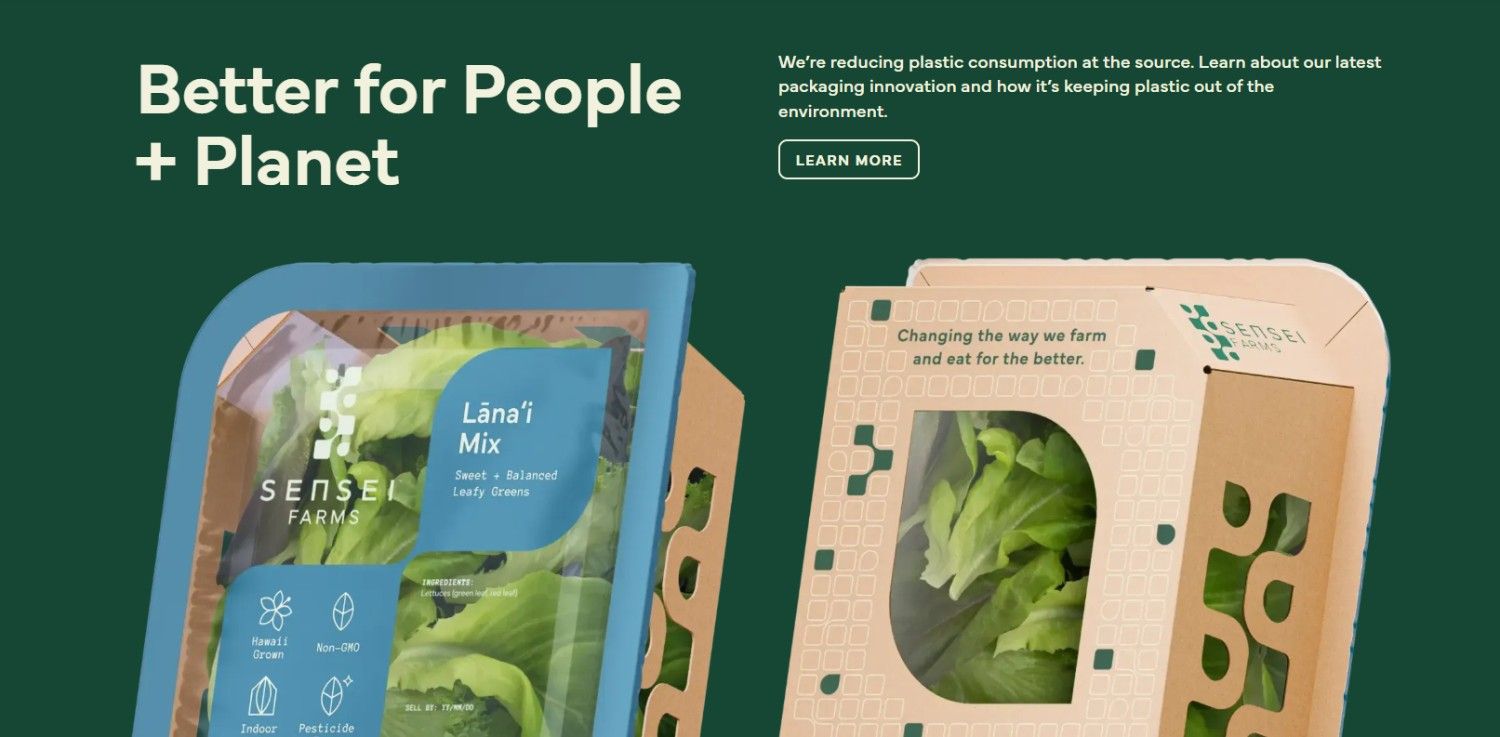

Brands need to craft clear, accurate consumer messaging and product packaging. Avoid the business consequences of “greenwashing” by honoring the FTC’s sustainability marketing guidelines, as outlined in the 2024 Green Guides update.

How is sustainable manufacturing program implementation similar to programs manufacturers already know? Take safety for example. Plant managers know that aspiring for “zero accidents” requires safety to be in everyone’s job description. EH&S leads the way with certain infrastructure and process changes. Ultimately, everyone in the organization receives role-appropriate training and upskilling. Sustainable manufacturing is very similar to driving positive safety outcomes. Third Partners helps leadership teams quickly identify economically-sound priorities, solve painful problems, and get everyone aligned on stepwise solutions that engage employees to quickly get from Point A to Point B to where you need to be.

Sustainable Strategies for Manufacturing: Double Materiality & Circularity

On top of making businesses more resilient to the effects of global environmental and humanitarian crises, sustainable manufacturing practices enable businesses to stay ahead of regulatory measures, gain competitive advantage, and protect brand equity with consumers.

Foundational to sustainable manufacturing, double materiality assessment and circularity principles empower manufacturing leadership teams to leverage sustainability as a differentiator across the entire business.

What is Double Materiality Assessment?

A double materiality assessment is an internal strategic planning process. It requires manufacturers to assess both financial and non-financial impacts across environmental and social dimensions. Unlike traditional materiality that concentrates on internal consequences, double materiality expands the scope to review external factors, offering a longer-term perspective on what sustainability actually encompasses for a company.

- Financial Materiality: Assess how environmental and social issues might impact company expenses, sales, and profit margins. How could climate change affect the continuity and affordability of our global supply chain?

- Environmental & Social Materiality: Evaluate how your company’s operations impact the environment and society. How do our international operations affect local ecology, waste management, and public health and wellbeing?

Manufacturers can use double materiality assessments to identify and prioritize sustainability efforts based on relevance and business impact

Double Materiality & Sustainable Manufacturing

The holistic approach of double materiality helps manufacturers develop strategy and recognize risks related to sustainability, such as resource scarcity or regulatory changes, enabling proactive management strategies.

- Inform Strategy

Create a roadmap outlining your company’s current baseline performance and future strategic direction on key sustainability and ESG-linked topics. A competent strategy includes:- Goals & Metrics: Define clear objectives and key performance indicators (KPIs)

- Action Plan: Develop a detailed action plan with milestones and timeline

- Resource Allocation: Devote adequate budget and employee bandwidth for sustainable investments, project management and implementation. It is uncommon for manufacturers to add new headcount strictly focused on sustainability. Training, upskilling and creating OKRs (objectives and key results) are more common tactics for distributing accountability.

- Framework Integration

Integrate double materiality into reporting frameworks and provide detailed disclosures and metrics on resource usage, emissions, waste management, social equity, and other key topics. As transparency is key to sustainability, these efforts fuel accountability and promise reliable progress tracking against sustainability goals and baselines. Manufacturers that are required to complete retailer-driven sustainability reporting and audits, such as EcoVadis or SEDEX-SMETA, will find that double materiality assessment better prepares the company for the intensive documentation requirements. - Regulatory & Industry Alignment

Stay up-to-date on evolving regulations and industry standards that emphasize double materiality. Readily adapting to new requirements ensures compliance and demonstrates commitment to stakeholders, investors and customers. Double materiality assessment is mandatory under the CSRD in the European Union.

What is Circularity?

Within the context of sustainability, circularity refers to the philosophy that resources retain value before, during and after production. As such, circularity focuses heavily on waste prevention. Due to the dual impact on profitability and environmental performance, circularity is almost guaranteed to be a materially significant issue for manufacturers to manage.

In a circular economy, raw materials and end products cycle through a closed-loop lifespan via reuse, repair, remanufacture, recycling and composting techniques.

Circularity is gaining traction in the manufacturing sector as more companies target energy efficiency and product development committed to longevity, repairability, and recyclability.

Circularity & Sustainable Manufacturing

Much more than just “recycling,” there are many benefits to closing loops in manufacturing processes. Circularity involves not only material flows, but also energy flows; for example, finding ways to reuse waste heat one process to provide lower temperature energy inputs into other processes. Echoing principles that are core to Lean Six Sigma, wherever there is waste, there is an opportunity to avoid a cost, increase efficiency or productivity. By implementing the core principles of circularity across the product lifecycle, manufacturers enhance product lifespan, minimize waste, and reduce dependency on virgin resources.

- Circular Design

- Design for Durability

Select high-quality materials and follow robust design principles to ensure products retain long-term utility, preventing the need for frequent replacements. - Design for Disassembly

Engineer products to be disassembled with ease, allowing for separation of materials that can be recycled or repurposed. Ideally, modular designs incorporate components that can be replaced and/or repaired individually. - Material Innovation

Research and develop new materials that are biodegradable or made from recycled content. Avoid or discontinue usage of PFAS and PFAS-containing materials.

- Design for Durability

- Circular Production

- Energy Efficiency & Renewable Energy

The adoption of energy-efficient technologies or renewable energy sources can significantly reduce a manufacturer’s carbon footprint. A production facility might utilize solar panels and smart energy storage to power its operations, for instance. - Modern Technology

Embrace innovative technologies to optimize resource utility and reduce waste. 3D printing, for example, allows for on-demand production that limits loss of material and streamlines inventory management. - Product Take-Back & Repair Programs

To close the circle, establish a product take-back or return and repair program. These programs ensure proper management of discarded products, and recover valuable materials that can be reintroduced into the manufacturing pipeline. Take-back works best in business-to-business contexts and may be appropriate for a select number of business-to-consumer transactions involving durable goods. We caution brands and manufacturers not to overstate the benefits of take-back programs for single-use or disposable materials, which may constitute greenwashing under emerging regulatory guidelines.

- Energy Efficiency & Renewable Energy

- Circular Supply Chain

To establish a circular supply chain, manufacturers should first implement stringent supplier standards and transparency initiatives, including supply chain mapping. Once all players in the supply chain have been identified, down to raw materials, manufacturers may identify strategic opportunities to utilize byproduct materials, switch from synthetics to bio-based ingredients, and engage suppliers to find novel sources of post-consumer recycled content for products and packaging.When it comes to claiming recycled material inputs, not all materials are created equal. Manufacturers may need to utilize third-party traceability frameworks, NGOs and consultants to certify materials from their point of origin, guaranteeing the integrity and sustainability of their supply chain. Just because a material is recycled does not mean it is sustainable. Human health and wellbeing in the first mile of supply chains is an emerging area where brands and manufacturers now have greater legal responsibility, thanks in part to U.S. and EU regulations including UFLPA and CSDDD. - Circular Culture

Training programs, internal awareness campaigns and widespread employee engagement ingrains sustainability as a tenet within the company’s identity and values, encouraging innovative thinking and genuine alignment with circular goals.

Benefits of Sustainable Manufacturing: The Bottom Line

Sustainable best practices produce environmental, social and economical benefits for manufacturers:

- Cost Savings: Sustainable manufacturing often generates cost savings by improving operational efficiency. Reduced waste and energy-efficient processes can lower utility bills and minimize raw material expenses.

- Brand Value & Market Position: Consumers increasingly prefer brands that demonstrate environmental & social responsibility. Sustainable practices can help companies stand out from the competition, potentially increasing market share and customer loyalty.

- Regulatory Risk Reduction: Proactive sustainable practices keep companies ahead of the curve with regulatory requirements, reducing liability and avoiding potential fines, penalties or reputational downfall.

- Strong Workforce: Companies with a strong commitment to sustainability appeal to a growing percentage of the workforce, requiring less time and resources to attract and retain top talent, especially among younger generations.

- Risk Mitigation: Long-term, sustainable practices mitigate risks associated with climate change, resource scarcity, and supply chain disruptions.

- ESG-Linked Financing: Investors and financial institutions increasingly value ESG performance as a piece of the valuation equation. Being able to demonstrate a record of sustainable manufacturing might qualify your company for new financing opportunities, lower-interest loans, green bonds, and more.

In Conclusion

Regulatory pressure and consumer demand for sustainable manufacturing will continue to climb in coming years. The practical application of double materiality assessment and circularity principles can redefine how manufacturers operate and empower systemic positive environmental and social change.

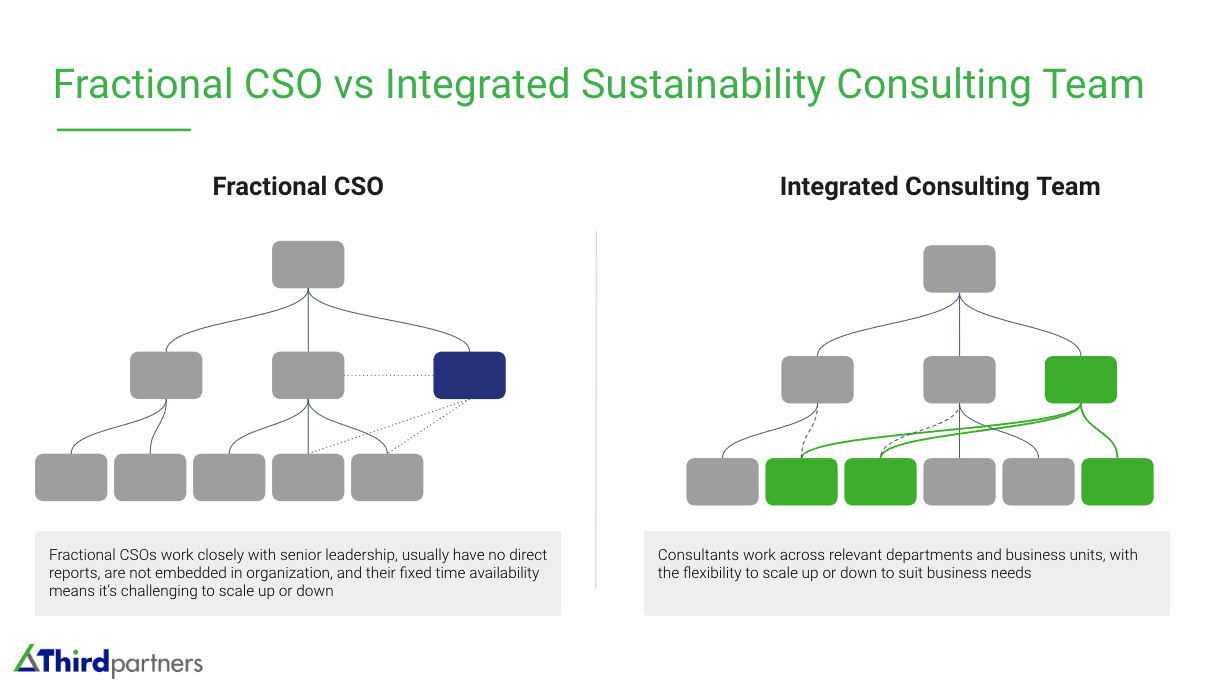

The team at Third Partners helps manufacturing clients simplify sustainability. Our services include 360-degree sustainable manufacturing audits, corporate level work such as materiality assessments and helping managers develop customized action plans with step-by-step initiatives.

Is sustainable manufacturing consulting a large investment for companies? Absolutely not. Many engagements are ROI-positive in the first year, based on provable cost reductions and sales growth-enabling outcomes alone. The total investment is typically a small fraction of energy- and waste-related costs that your business incurs daily. How?

1. We partner with your EH&S, operations, engineering, R&D, and plant finance leaders to educate, upskill, empower, and support. Sustainability cannot be outsourced. Build your sustainable manufacturing competency from within.

2. We help you leverage State and Federal programs including technical assistance for energy efficiency studies and implementation grants that provide free engineering support, including the U.S. Department of Energy’s Better Plants program.

3. We support topline business growth by partnering with marketing & brand executives. Many manufacturers struggle with staying compliant with marketing claims around environmental impact. These claims are critical in order to differentiate from competitors, attract investment, and meet buyer expectations. Getting it wrong or failing to substantiate claims scientifically can have huge costs to your business.

Don’t hire just any consultant when you can hire a partner. For example, it is critical to leverage free and subsidized technical assistance programs and cleantech implementation grants available to U.S. manufacturers through Federal programs including the U.S. DOE’s Better Plants program. In addition, we’ve helped manufacturers enroll in State and Local programs in partnership with universities, labs, and cities.

As independent consultants we help companies objectively navigate the fastest, highest-ROI solutions to solve a variety of energy, supply chain, and reporting-related problems.

Contact us for a free consultation to learn more.